- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Construction & Real Estate

- General Mechanical Equipment Refrigeration Equipment Metal & Metallurgy Machinery Other Equipments

- Safety Roadway Safety Personal Protective Equipment

- Mechanical Basic Parts Bearing Spare Parts

- Hardware Tools

- Instrumentation Testing and Analysis Instruments Other Instrumentations

- Electrical & Electronics

- Construction Machinery Lifting Machinery Earth Moving machinery Road Construction Machinery Drilling Machinery Logistics Machinery Generator Set & Engine Other Machinery

- Rubber & Plastics Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System PCTFE Product Polymer Material

- Industrial Gas Container

- Hotel Equipment & Supplies

- Daily Necessities Fabric Products Glasswork Pet Supplies

- Environmental Protection Machinery

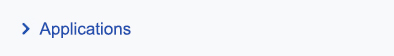

Safety Nets

Material: PE rope, PP rope, Nylon rope, Polyester rope, Vinylon rope

Types: vertical, horizontal and fine mesh vertical safety net

Shanghai Metal Corporation is leading manufacturer of safety nets in China since 1980s.

Safety nets are safety facilities designed to prevent personnel or objects from falling, consisting of a net body, boarder ropes, tie ropes, and tendon ropes. The safety nets is made from materials such as high-density polyethylene and nylon, they feature corrosion resistance and anti-aging properties, which primarily is used in high-altitude work environments like construction, manhole protection, and equipment installation. These nets can be divided into horizontal safety nets, vertical safety nets and fine mesh vertical safety nets.

If you want to know more about safety nets, please feel free to contact us, we will reply you within 24 hours.

Technical Requirements of Safety Nets:

1. The safety net can be made of nylon, viscose, polyester or other materials with weather resistance not lower than the above varieties.

2. The height of the flat net shall not be less than 3m, the width of the vertical net shall not be less than 1.2m, and the width (height) of the dense mesh safety net shall not be less than 1.2m. Product specification deviation: allowable within ± 2%. The weight of each safety net should generally not exceed 15kg.

3. Safety nets with diamond or square mesh, with a mesh length not exceeding 8cm.

4. The connection between the edge rope and the net body must be firm, and the breaking force of the flat net edge rope shall not be less than 7000N; the breaking tension of the vertical net edge rope shall not be less than 3000N.

5. The ropes should be evenly distributed along the edge of the net, and the distance between adjacent ropes should comply with the provisions of Table 1. The length shall not be less than 0.8m. When the reinforcement and tying rope are used together, the tying rope part must be lengthened and tied to the side length, and then folded back to tie the edge rope tightly, forming at least two strands.

6. The distribution of reinforcement ropes should be reasonable, with a distance of no less than 30cm between two adjacent ropes on the flat net, and the breaking strength of the ropes should not exceed 3000N.

7. The breaking strength of the mesh should comply with the corresponding product standards.

8. All nodes of the safety net must be fixed.

9. Conduct the test according to the safety net impact test method.

10. The flame retardant safety net must have flame retardancy, and its continuous combustion and smoldering time must not exceed 4 seconds.

Packaging of Safety Nets:

Products of SHANGHAIMAC are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

here

for

price