- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Construction & Real Estate

- General Mechanical Equipment Refrigeration Equipment Metal & Metallurgy Machinery Other Equipments

- Safety Roadway Safety Personal Protective Equipment

- Mechanical Basic Parts Bearing Spare Parts

- Hardware Tools

- Instrumentation Testing and Analysis Instruments Other Instrumentations

- Electrical & Electronics

- Construction Machinery Lifting Machinery Earth Moving machinery Road Construction Machinery Drilling Machinery Logistics Machinery Generator Set & Engine Other Machinery

- Rubber & Plastics Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System PCTFE Product Polymer Material

- Industrial Gas Container

- Hotel Equipment & Supplies

- Daily Necessities Fabric Products Glasswork Pet Supplies

- Environmental Protection Machinery

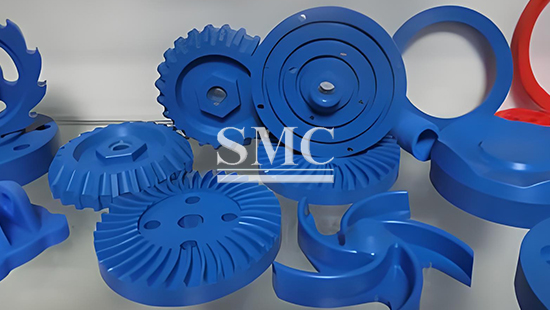

PPSU Injection Molding

Material: PPSU

Color: Nature, blue, black, etc.

Size: Customized

Shanghai Mac is a leading manufacturer and supplier of PPSU Injection Molding.

Polyphenylsulfone (PPSU) is an injection-molded plastic that resists high temperatures and harsh chemicals. Injection-molded PPSU parts are also tough, dimensionally stable, and impact-resistant. They can withstand steam autoclaving, hot water with detergents, and other demanding conditions. Filled and reinforced grades of this material are also available.

|

PPSU Specification |

|||

|

Item |

Value |

Test standard |

Unit |

|

Density |

1.29 |

ISO 1183 |

g/cm³ |

|

Tensile Strength |

70 |

ISO 527 |

MPa |

|

Yield Strength |

60-120 |

ISO 527 |

% |

|

bending modulus |

2650 |

ISO 178 |

MPa |

|

Impact strength (notch) |

7 |

ISO 180 |

kJ/m² |

|

Heat deflection temperature(1.8MPa) |

207 |

ISO 75 |

°C |

|

Continuous working temperature |

180 |

- |

°C |

|

melting point |

360 |

ISO 11357 |

°C |

|

dielectric strength |

16 |

IEC 60243 |

kV/mm |

|

volume resistivity |

10¹⁶ |

IEC 60093 |

Ω·cm |

Above data are for reference only. There may be differences among different batches. The actual production and delivery shall prevail

Packaging of PPSU Tube/Pipe

Shanghai MAC Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. Paper carton, Pearl cotton carton, Wooden Case is adopted. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai MAC Standard

2) Customization

PPSU injection molding process

Design: The first step is to create a detailed design of the part or component to be produced. This involves determining the dimensions, features, and structural requirements of the final product.

Mold preparation: A mold is created, usually made of steel or aluminum, that has a cavity in the shape of the desired part. The mold consists of two halves: the stationary half (the “cavity”) and the moving half (the “core”). The mold is precision machined to ensure accurate replication of the part.

Material preparation: PPSU is supplied in the form of pellets or granules. The material is dried to remove any moisture, as moisture can affect the quality of the final product. The dried PPSU pellets are then loaded into a hopper of the injection molding machine.

Injection molding machine setup: The injection molding machine is set up by adjusting various parameters such as temperature, injection pressure, and injection speed. These settings may vary depending on the specific grade of PPSU being used.

Injection: The PPSU pellets are fed into a heated barrel of the injection molding machine. Inside the barrel, the pellets are melted under high temperature and pressure. Once the material reaches the molten state, it is injected into the mold through a nozzle and sprue system.

Cooling and solidification: After the molten PPSU fills the mold cavity, it begins to cool and solidify. Cooling can be accelerated by circulating coolant or water through channels in the mold. The cooling time is carefully controlled to ensure the proper solidification of the material.

Mold opening and ejection: Once the PPSU has solidified, the mold is opened, and the part is ejected. The moving half of the mold (core) is pushed away from the stationary half (cavity), and the part is released using ejector pins or plates.

Post-processing: Depending on the specific requirements, the molded PPSU part may undergo additional post-processing steps. This may include trimming excess material, surface finishing, and any necessary assembly or quality checks.

The injection molding process allows for efficient and high-volume production of complex PPSU parts with consistent quality and dimensional accuracy. It is widely used in various industries due to its versatility and cost-effectiveness.

here

for

price